This post details how under the influence of Serendipity I am discovering underlying connections between spheres, rhombic dodecahedrons, the Widget toy, the Nodlet truss and geometric matrices. This underlying silver thread of connectivity leads me on to yet further insights.

Leading question.........What is the hardest thing to package? I nailed the speaker at the bar and asked him.

Answer........................"Balls!", he answered.

Question......................What is the perfect packing design for a sphere? I thought I knew the answer to this riddle. I thought it was the pentagonal dodecahedron (PD). In 1970 I had built a scale model building for my younger brother George's "Scalextric" racing car set incorporating a PD as a conning tower.

What is a pentagonal dodecahedron

Boy, was I wrong! After this conference I spent nearly 6 months of late nights before I eventually found, through geometry and bubble baths, what the perfect packaging was for a sphere!

.

Invention.......................at last....I thought it was unique, I named it the "Parallella-pipoid dodecahedron".

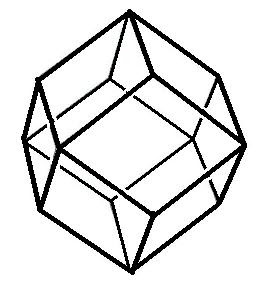

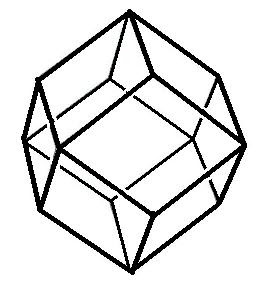

The existence of this convex polyhedron with 12 parallelogram shaped faces, I was later to discover, was known as the rhombic dodecahedron.

It was discovered, not as is generally thought, by Johannes Kepler (1571-1630), but by Archimedes the ancient Greek mathematician, physicist and engineer who died in 212BC.

Mother Nature actually beat us all to the punch .....pomegranate seeds for just a starter.

What is a rhombic dodecahedron.

Result ..........................Provisionally patented as a “Space Saving Packaging Design for a Sphere”

Well, I proposed the idea to our family business of J.W.Moore Ltd.

I figured that with maybe 50 girls in the bindery department making up RD's by assembling and gluing together, pre-punched & creased templates, they would become fully employed. We could then market them to companies who made balls and who were then packing the balls into cubic shaped boxes. You can store more balls in a given warehouse space if you pack them in RD's rather than in cubic boxes.

My Uncle Bob (yes, Bob was my uncle) who also happened to be the Vice President didn't quite grasp the concept at all.

Packing of spheres

Second Encounter. (10 years later)

When?..................................1982

Where?.................................Saudi Arabia, Eastern Province of Khobar.

Who?.....................................The Kuwait Bank Building Construction Project

What?....................................The bank was constructed of four corner piers, which supported a huge tetrahedral truss system from which the fabric of the building was suspended.

Question................................Could a rhombic dodecahedron be a stable structure when constructed from rods and nodes?

Invention................................Build a skeletal rhombic dodecahedron (RD) model incorporating a common hexagonal node design with six bearing journals to which the rods ends are attached and free to pivot. My prototype was made from drinking straws and bent paper clips.

Result.....................................The RD was not stable and could freely flex at the nodes.

It did however display a disciplined geometrical folding movement, which was unique allowing the structure to assume a variety of different hexagonal shapes. I designed a toy proto-type which was made by an engineering and modelling company in Newcastle upon Tyne and three months later forwarded to me in Saudi.

Result...............................provisionally patented later in 1985 as a “Framework of Changeable Shape”

The Widget Toy

Toy Patent: framework of changeable shape

Circa November 7th 1984.

Steve Jennings, my good friend whom I had met in Saudi, sent me a newspaper cutting from the Innovation page of the Daily Telegraph showing a system of rods and nodes which looked very much like the toy I had invented.

It was for use in outer space as a reflector dish.

I contacted the co-inventors of this collapsible antenna dish. I was invited to visit them at Guildford University in Surrey England at the Space Structures Centre.

I was introduced to Dr Nooshin and Dr R. Annandale. and four other associates.

Their invention was shown to me which was in effect a tetrahedral truss incorporating midpoint foldable pin joints.

I showed them my widget toy. After due consideration, they concluded that it would be impossible to make a viable expandable stable truss from it unless it incorporated mid point hinges.

I showed them my widget toy. After due consideration, they concluded that it would be impossible to make a viable expandable stable truss from it unless it incorporated mid point hinges.

I had to agree as it seemed that the Widget toy was incapable of any configuration that would be able to support weight or span any distance.

Disappointed, I thanked the Doctors for their time and patience.

Upon my departure I gave each doctor one of my nodes to keep for posterity.

Third Encounter.

7 years later……………..

When?.........................................1990

Where?.......................................The Schoolhouse. Escrick, Yorkshire, England.

Who?..........................................Jessica and I.

It was a somewhat delicate prototype. The model maker used too much talcum powder as a filler in the plastic to achieve the "click" as the rod end engages on the node's journals. The rod ends kept snapping off. Jessica was born in 1985. Here we were 5 years later and Jessica was now tall enough to reach the Widget.on the upper shelf where I had kept it. A pet lip from Jessica when I showed the fear of collateral damage

The toy had already been rejected by the toy industry there was really no reason to be so damn neurotic about keeping it away from Jess anymore.

So we put it on the table and began to play with it.

Oh oh!! It slid right off the table and with the action of both of us trying to catch it at the same time, it spun to the floor...... and then......and then..... it turned inside out and folded up into this really compact bundle of vertical rods, a shape that it had never assumed before.

Ding ding! The lights went on in my head....I recognised that with the addition of tension wires I could make a stable tensegrity truss.

I guess I had what Pasteur had called the "prepared mind"

Invention...................................the Nodular Octahedral Double-Layered Expandable Truss.

I built a prototype using threaded rods, hexagonal metal nodes and ripcloth acting as tensegrity skin membranes.

Result.......................................

I again set forth to the Space Structure Centre to see Dr Nooshin of the Space Structures Centre at Guildford University in Surrey. He gathered a team of experts in the field of folding spaceframes and after an hour or so I was advised that I had indeed discovered a new tensegrity truss. They were amazed at its simplicity and elegance.

A short report was published in the International Journal of Space Structures. (Volume 6 No 1. 1991)

View Nodlet blog.

More Nodlet Photos.

See video of Nodlet.

First Encounter.

When?.........................In January 1972

I had left the the Royal Air Force (1965-1971) and had joined the family business of J.W.Moore, Printers and Bookbinders in North Shields, Tyne & Wear. North East England. (Geordie-land..." Haway the Lads!!")

I fell in love, was engaged for a year and was happily married to Susan Russell in 1972 on December the 21st...Sue's birthday.

Howard Christie was, and still is, our best man.

I was at Newcastle University and was learning to be a Master Printer at the School of Print.

Bill, my father had given me "carte blanche" on which conferences or seminars I wanted to attend in order to broaden my knowledge base.

One of the major problems J.W.M. Ltd was having, was a shortage of work in the binding department. Hmmmmm.............................?????

Where?........................

I had left the the Royal Air Force (1965-1971) and had joined the family business of J.W.Moore, Printers and Bookbinders in North Shields, Tyne & Wear. North East England. (Geordie-land..." Haway the Lads!!")

I fell in love, was engaged for a year and was happily married to Susan Russell in 1972 on December the 21st...Sue's birthday.

Howard Christie was, and still is, our best man.

I was at Newcastle University and was learning to be a Master Printer at the School of Print.

Bill, my father had given me "carte blanche" on which conferences or seminars I wanted to attend in order to broaden my knowledge base.

One of the major problems J.W.M. Ltd was having, was a shortage of work in the binding department. Hmmmmm.............................?????

Where?........................

Who?...........................The metal Box Co. Manchester.

What?..........................Conference entitled “Printing and Packaging”

My Intent.................Looking for a difficult product to specialize inLeading question.........What is the hardest thing to package? I nailed the speaker at the bar and asked him.

Answer........................"Balls!", he answered.

Question......................What is the perfect packing design for a sphere? I thought I knew the answer to this riddle. I thought it was the pentagonal dodecahedron (PD). In 1970 I had built a scale model building for my younger brother George's "Scalextric" racing car set incorporating a PD as a conning tower.

What is a pentagonal dodecahedron

Boy, was I wrong! After this conference I spent nearly 6 months of late nights before I eventually found, through geometry and bubble baths, what the perfect packaging was for a sphere!

.

Invention.......................at last....I thought it was unique, I named it the "Parallella-pipoid dodecahedron".

The existence of this convex polyhedron with 12 parallelogram shaped faces, I was later to discover, was known as the rhombic dodecahedron.

It was discovered, not as is generally thought, by Johannes Kepler (1571-1630), but by Archimedes the ancient Greek mathematician, physicist and engineer who died in 212BC.

Mother Nature actually beat us all to the punch .....pomegranate seeds for just a starter.

What is a rhombic dodecahedron.

Result ..........................Provisionally patented as a “Space Saving Packaging Design for a Sphere”

Well, I proposed the idea to our family business of J.W.Moore Ltd.

I figured that with maybe 50 girls in the bindery department making up RD's by assembling and gluing together, pre-punched & creased templates, they would become fully employed. We could then market them to companies who made balls and who were then packing the balls into cubic shaped boxes. You can store more balls in a given warehouse space if you pack them in RD's rather than in cubic boxes.

My Uncle Bob (yes, Bob was my uncle) who also happened to be the Vice President didn't quite grasp the concept at all.

Packing of spheres

Second Encounter. (10 years later)

When?..................................1982

Where?.................................Saudi Arabia, Eastern Province of Khobar.

Who?.....................................The Kuwait Bank Building Construction Project

What?....................................The bank was constructed of four corner piers, which supported a huge tetrahedral truss system from which the fabric of the building was suspended.

Question................................Could a rhombic dodecahedron be a stable structure when constructed from rods and nodes?

Invention................................Build a skeletal rhombic dodecahedron (RD) model incorporating a common hexagonal node design with six bearing journals to which the rods ends are attached and free to pivot. My prototype was made from drinking straws and bent paper clips.

Result.....................................The RD was not stable and could freely flex at the nodes.

It did however display a disciplined geometrical folding movement, which was unique allowing the structure to assume a variety of different hexagonal shapes. I designed a toy proto-type which was made by an engineering and modelling company in Newcastle upon Tyne and three months later forwarded to me in Saudi.

Result...............................provisionally patented later in 1985 as a “Framework of Changeable Shape”

The Widget Toy

Toy Patent: framework of changeable shape

Circa November 7th 1984.

Steve Jennings, my good friend whom I had met in Saudi, sent me a newspaper cutting from the Innovation page of the Daily Telegraph showing a system of rods and nodes which looked very much like the toy I had invented.

It was for use in outer space as a reflector dish.

I contacted the co-inventors of this collapsible antenna dish. I was invited to visit them at Guildford University in Surrey England at the Space Structures Centre.

I was introduced to Dr Nooshin and Dr R. Annandale. and four other associates.

Their invention was shown to me which was in effect a tetrahedral truss incorporating midpoint foldable pin joints.

I had to agree as it seemed that the Widget toy was incapable of any configuration that would be able to support weight or span any distance.

Disappointed, I thanked the Doctors for their time and patience.

Upon my departure I gave each doctor one of my nodes to keep for posterity.

Third Encounter.

7 years later……………..

When?.........................................1990

Where?.......................................The Schoolhouse. Escrick, Yorkshire, England.

Who?..........................................Jessica and I.

It was a somewhat delicate prototype. The model maker used too much talcum powder as a filler in the plastic to achieve the "click" as the rod end engages on the node's journals. The rod ends kept snapping off. Jessica was born in 1985. Here we were 5 years later and Jessica was now tall enough to reach the Widget.on the upper shelf where I had kept it. A pet lip from Jessica when I showed the fear of collateral damage

The toy had already been rejected by the toy industry there was really no reason to be so damn neurotic about keeping it away from Jess anymore.

So we put it on the table and began to play with it.

Oh oh!! It slid right off the table and with the action of both of us trying to catch it at the same time, it spun to the floor...... and then......and then..... it turned inside out and folded up into this really compact bundle of vertical rods, a shape that it had never assumed before.

Ding ding! The lights went on in my head....I recognised that with the addition of tension wires I could make a stable tensegrity truss.

I guess I had what Pasteur had called the "prepared mind"

Invention...................................the Nodular Octahedral Double-Layered Expandable Truss.

I built a prototype using threaded rods, hexagonal metal nodes and ripcloth acting as tensegrity skin membranes.

Result.......................................

I again set forth to the Space Structure Centre to see Dr Nooshin of the Space Structures Centre at Guildford University in Surrey. He gathered a team of experts in the field of folding spaceframes and after an hour or so I was advised that I had indeed discovered a new tensegrity truss. They were amazed at its simplicity and elegance.

A short report was published in the International Journal of Space Structures. (Volume 6 No 1. 1991)

More Nodlet Photos.

See video of Nodlet.

Fourth Encounter.

7 years later……………

When?......................................1997

Where?....................................Manoa, Honolulu, Hawaii

Who?.........................................Self

What?........................................Given that only three nodlet trusses had been hand modeled, my claim that a number of conjoined trusses would exhibit multiple surface curvature was questioned on the grounds that the apparent formability of the three conjoined trusses was due to "slop" at the nodal connections and formability was therefore not a true attribute of the “Nodlet”.

Question.....................................How can I build more economic trusses to enable me to verify my claim?

Whilst I was pondering upon this problem, my attention was drawn to the cover of a book that I had been reading that Tom Prince had gifted me a few days earlier, called 'The Sense of Unity'. There by golly gosh lay the answer! Answer.......................................Using cardboard, I made the nodes as large hexagons and the rods as squares with the sides of the squares and hexagons being equal in length which were all then cut out of one sheet and then folded into the truss configuration.

In order to make a true copy of the Nodlet it would be necessary to add additional hexagons to the folded flat sheet component.

In the interests of proving the flexibility, it was unnecessary to go to that bother. The free-ended un-adjoined squares were removed from the flat sheet component, which resulted in………………

Invention..................................Hexaflex…………An extremely flexible pseudo honeycomb matrix design.

More Hexaflex images

When?......................................1997

Where?....................................Manoa, Honolulu, Hawaii

Who?.........................................Self

What?........................................Given that only three nodlet trusses had been hand modeled, my claim that a number of conjoined trusses would exhibit multiple surface curvature was questioned on the grounds that the apparent formability of the three conjoined trusses was due to "slop" at the nodal connections and formability was therefore not a true attribute of the “Nodlet”.

Question.....................................How can I build more economic trusses to enable me to verify my claim?

Whilst I was pondering upon this problem, my attention was drawn to the cover of a book that I had been reading that Tom Prince had gifted me a few days earlier, called 'The Sense of Unity'. There by golly gosh lay the answer! Answer.......................................Using cardboard, I made the nodes as large hexagons and the rods as squares with the sides of the squares and hexagons being equal in length which were all then cut out of one sheet and then folded into the truss configuration.

In order to make a true copy of the Nodlet it would be necessary to add additional hexagons to the folded flat sheet component.

In the interests of proving the flexibility, it was unnecessary to go to that bother. The free-ended un-adjoined squares were removed from the flat sheet component, which resulted in………………

Invention..................................Hexaflex…………An extremely flexible pseudo honeycomb matrix design.

More Hexaflex images

View Hexaflex blog

See video of Hexaflex.

More video

Hexaflex Patent.

Fifth Encounter.

17th February 2012

More pennies from Heaven

This realisation is profound. The Nodlet is a truss mechanism I discovered in 1990 which can be opened and closed by manipulating two opposed nodes. By a stroke of coincidence I have found a mechanical system which can warp two-dimensional space into three dimensions and control the degree of warpage by remote control. Now there is a means to emulate the movement of a snake which can slither into all sorts of tight locations.....possibly to locate victims of building collapse.

This realisation is profound. The Nodlet is a truss mechanism I discovered in 1990 which can be opened and closed by manipulating two opposed nodes. By a stroke of coincidence I have found a mechanical system which can warp two-dimensional space into three dimensions and control the degree of warpage by remote control. Now there is a means to emulate the movement of a snake which can slither into all sorts of tight locations.....possibly to locate victims of building collapse.

By using Shape Metal Alloys (SMA's), servo motors or compressed air systems located in the voids created when two sheets of Hexaflex are overlaid upon themselves this geometry allows a means of morphing a planar surface of Hexaflex into any form of surface curvature by changing the distance between the many dual-opposed nodes.

See video of Hexaflex.

More video

Hexaflex Patent.

Fifth Encounter.

17th February 2012

More pennies from Heaven

Tonight I folded my large sheet of Hexaflex on top of itself in a similar fashion as if one were closing an open book. Amazingly the Nodlet Truss mechanism appea rs.

rs.

Nodlet

rs.

rs.Nodlet

This realisation is profound. The Nodlet is a truss mechanism I discovered in 1990 which can be opened and closed by manipulating two opposed nodes. By a stroke of coincidence I have found a mechanical system which can warp two-dimensional space into three dimensions and control the degree of warpage by remote control. Now there is a means to emulate the movement of a snake which can slither into all sorts of tight locations.....possibly to locate victims of building collapse.

This realisation is profound. The Nodlet is a truss mechanism I discovered in 1990 which can be opened and closed by manipulating two opposed nodes. By a stroke of coincidence I have found a mechanical system which can warp two-dimensional space into three dimensions and control the degree of warpage by remote control. Now there is a means to emulate the movement of a snake which can slither into all sorts of tight locations.....possibly to locate victims of building collapse.By using Shape Metal Alloys (SMA's), servo motors or compressed air systems located in the voids created when two sheets of Hexaflex are overlaid upon themselves this geometry allows a means of morphing a planar surface of Hexaflex into any form of surface curvature by changing the distance between the many dual-opposed nodes.

In the above sequence of images, for illustrative purposes, the SMA's are depicted by the brown wooden blocks.

I have found the perfect material for the inner and outer skins of my snake cylinder concept.

It is called "Metal Rubber" made by Nanosonic.Inc

http://www.nanosonic.com/MR-01-sensors_productdatasheet.pdf

This helps solve the power distribution to the SMA's By making one of the skins having a positive polarity and the other skin a negative polarity.

Who would have thought that ............

This helps solve the power distribution to the SMA's By making one of the skins having a positive polarity and the other skin a negative polarity.

Who would have thought that ............